Material details

Wheatering steel

The COR-TEN sheet is supplied free of oxidation. Read the “Technical details” sheet for all information on this material.

Available thicknesses: 1.5mm, 2mm, 3mm, 5mm

Description

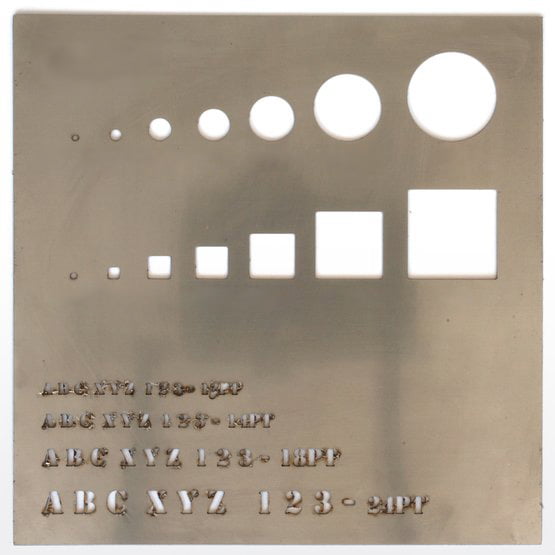

The laser cutting process on metals is different than the other materials in the catalog. Before proceeding with laser cutting on metal, be sure to read these important indications:

- it is not possible to share cutting lines

- you will only receive the cut pieces, not the rest of the plate. It is not possible to receive both positive and negative. If you intend to make a stencil you need to draw the border around your design and you will only receive the template.

- the objects must have an area of at least 10x10mm (the grid on which the slab rests is very large, the smaller pieces of this size will fall and it will not be possible to recover them)

- the elements on the template must be 6mm apart from each other

- it's better avoid details with a width of less than 1mmbecause they could be burned away and not be on the final object

- it is also necessary to create "carrier" details of width equal to or greater than the thickness of the material. In any case never less than 1mm. For example, if I choose to use a 3mm plate, the minimum thickness within my design should be 3mm. If I choose to use a plate with a thickness of 0.5mm, the minimum thickness within the design must be 1mm.

- draw using only closed paths

- before cutting an object, the laser can drill on the outside of the cutting line

- in the smaller elements, the corners may be rounded

- the back of the material will be slightly satin for the process of cleaning and removing the burns after cutting

- on COR-TEN we advise against making incisions as they will no longer be visible once rusty

- you can make engravings using medium vector engraving (green color). It is not possible to make engravings of different intensity or raster engraving.

- If in doubt write a note before adding the drawing to the cart!

Technical details

Steel COR-TEN has high weathering resistance and a very typical appearance, making it frequently used in architecture and for the

Making sculptures.

The name COR-TEN comes from the characteristics of the material:

Corrosion resistance (CORrosion resistance) and stress resistance (TENsile strength).

COR-TEN before undergoing oxidation looks like ordinary black sheet metal. Over time it will take on its characteristic appearance.

Complete natural oxidation takes about 18/36 months, but the effect is visible as early as 6 months.It can also be practiced in 48 hours with chemical accelerants.

The color can vary over time from orange to red-brown to dark brown.

Oxidation creates a protective coating consisting of the oxides of its alloying elements, which prevents corrosion of the material.

In order for the surface patina of "rust" to form, it is necessary to keep the material exposed to the weather, alternating cycles of wetting and

drying; however, the water must not create stagnation on the surface.

In the absence of these events, the surface patina does not form and COR-TEN behaves like normal iron.

Seawater is not functional in creating the surface film.

COR-TEN sheets are mainly used for creating signs, tables, sculptures, borders and other outdoor decorations.