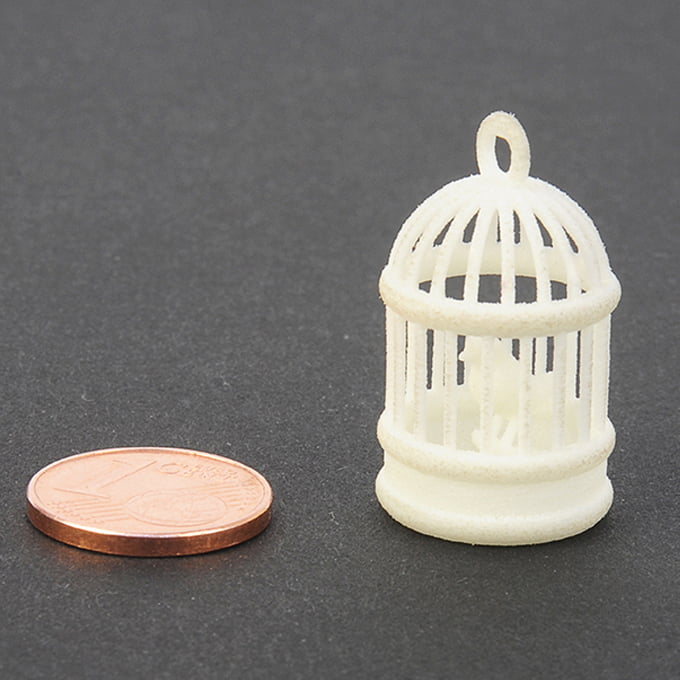

Material details

White plastic (laser sintered nylon) for 3D printing

Appearance: • • • •

Details: • • • •

Resistance: • • • • •

Flexibility: • • •

- Economic

- Resistant

- Flexible

Description

This material consists of a sintered laser polyamide (nylon) powder (SLS, Selective Laser Sintering). It is an extremely versatile material, which can be flexible in the low thicknesses, but can have such resistance as to make it ideal for the 3D printing of parts with a structural need. Objects are created by a laser beam that "draws" the object on a layer of powder, solidifying it, layer by layer. Once printed in white polyamide, the objects are immersed in a dye bath.

Elements with a minimum thickness of 0.8mm can be printed: in this case the parts are flexible and can be bent. Above 2mm in thickness, the elements become rigid. Nylon printed in 3D lends itself as a material to create objects from different uses, from aesthetic prototypes to functional objects such as covers for electronic devices, box mods, up to jewels.

Maximum printable volume: 677 mm x 368 mm x 565 mm

(production costs can be optimized not exceeding a volume of 180 x 230 x 300 mm)

You can not insert multiple objects into a single template / file.

- Moving parts: Yes

- Watertight: No

- For food: No

- Suitable for dishwashers: Yes

- Recyclable: No

- Heat resistant up to 80 ° C

- Thickness of the layers: 0.1mm

To know all the rules to be followed to create a model with this material, consult the Technical Details tab.

Technical details

DIMENSIONS

Maximum: X + Y + Z = 180 x 220 x 220 mm

Minimum: X + Y + Z = 7.5 mm

WALL THICKNESS:

Minimum wall thickness: 0.8 mm

OTHER DETAILS:

minimum size for object details: 0.2 mm

spill hole of the non-sintered material: minimum 4mm

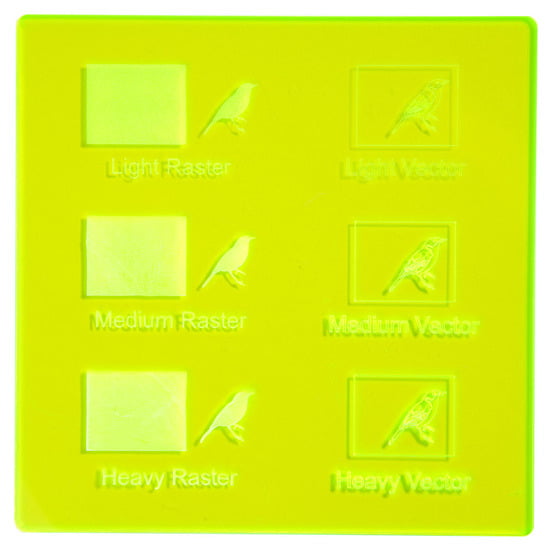

TEXT:

for embossed text: min 0.5 mm thick

for engraved text: min 0.5 mm depth

To know precisely all the mechanical and thermal properties of the material, download the technical sheet.